Custom Furniture Terms:

Design:

Design meetings with decorators or clients at our shop or at clients home will be done at no charge.

Once all measurements and details have been finalized an estimate will be given. Please confirm all detailed instructions and measurements on your estimate/invoice.

Deposit:

50% deposit requested on all custom orders prior to construction.

Any changes to custom orders after furniture has been constructed will be charged by the hour.

Completion Time:

Average time from start to finish on custom orders change depending weeks from time of deposit.

Delivery:

Delivery service is available for a fee: Depending on the weight of finished items.

Check to see if you are considered local or non-local.

Frames:

All frames are made up of dried hardwood. They are dowelled and glued, with corner block bracing, and are guaranteed for life under regular use.

New frames are offered with 8 way hand tied coil springs, no sag springs or rubber webbing options.

We have constructed furniture in excess off 110” in length and 43” in depth. Due to the extreme weight of our custom pieces we will not offer delivery on items that go over a certain weight limit. Professional movers will be needed.

Important: When ordering larger size furniture we must first make sure it will fit into the desired location. Alterations can be made prior to construction.

Knops Upholstery reserve the right to duplicate any custom furniture they manufacture.

Custom Beds And Headboards:

Any standard or Custom size available.

Fully upholstered beds that include side rails and footboard are delivered in sections and joined together with a locking mechanism. Also included with a slat support system.

Upholstered Headboards are also assembled with bolts to the existing metal bed frame.

Installation charges will apply.

Custom Sectionals:

Any custom size available (Smallest sections starting at 24”W).

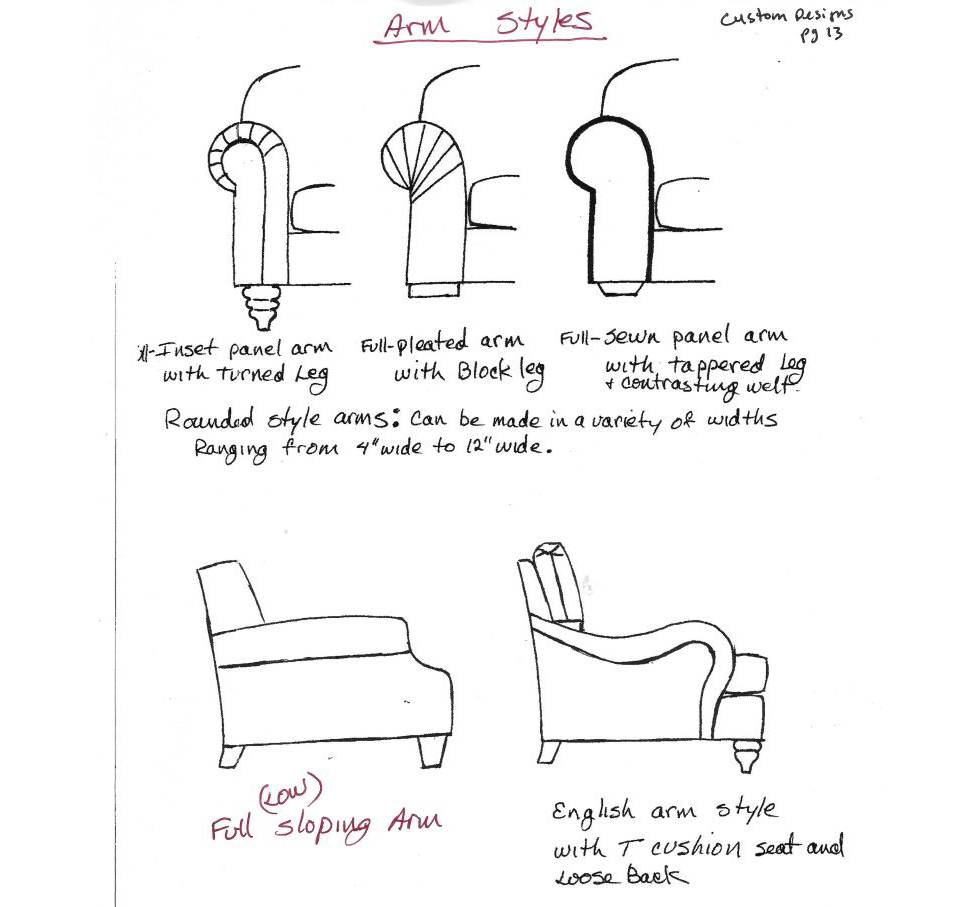

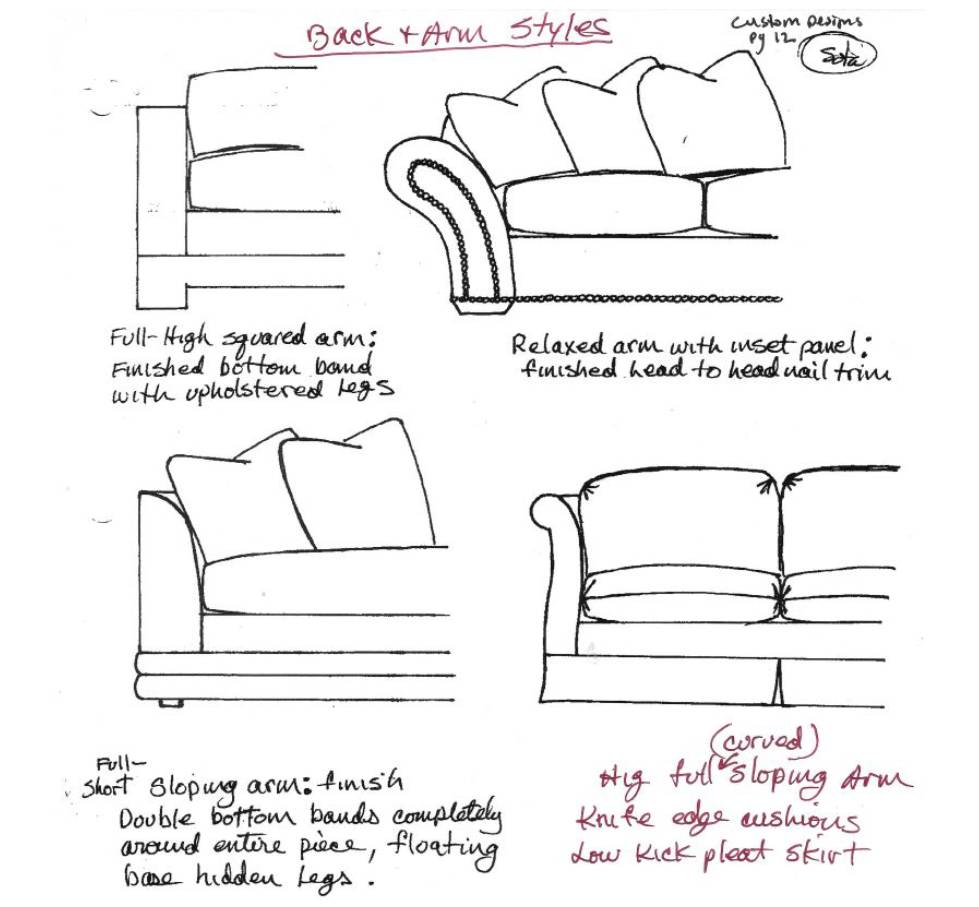

Sectionals can be made with most arm styles: English arm, Rounded, and Square arms (Different arm thickness and heights are also available).

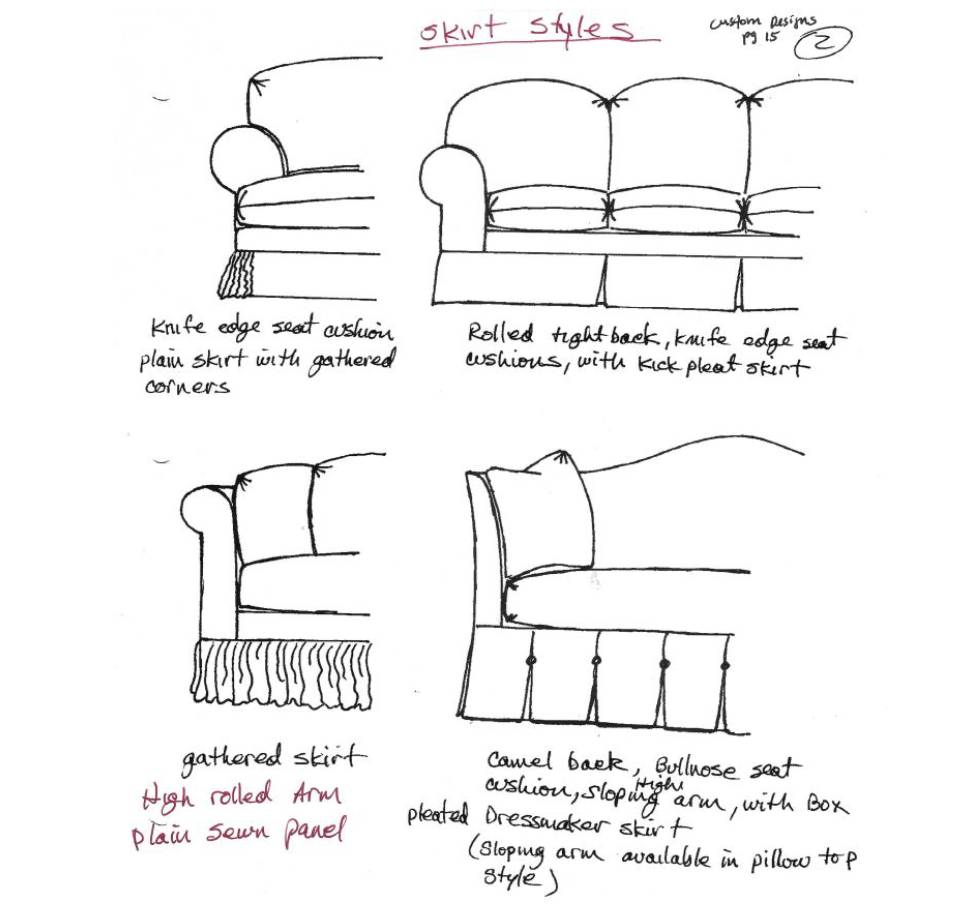

Any base finish is available including dressmaker skirt, floating base, or nail trim combinations.

Seat & Back Cushion Styles

Boxed Style: Has aesndua o4 finish look, and a seam that goes completely around This style cushion can be finished with or without welting. Single or double topstitching (baseball stitch) is also available. Note: Topstitching is not recommended on velvets, fabrics with ribs, or deep textures.

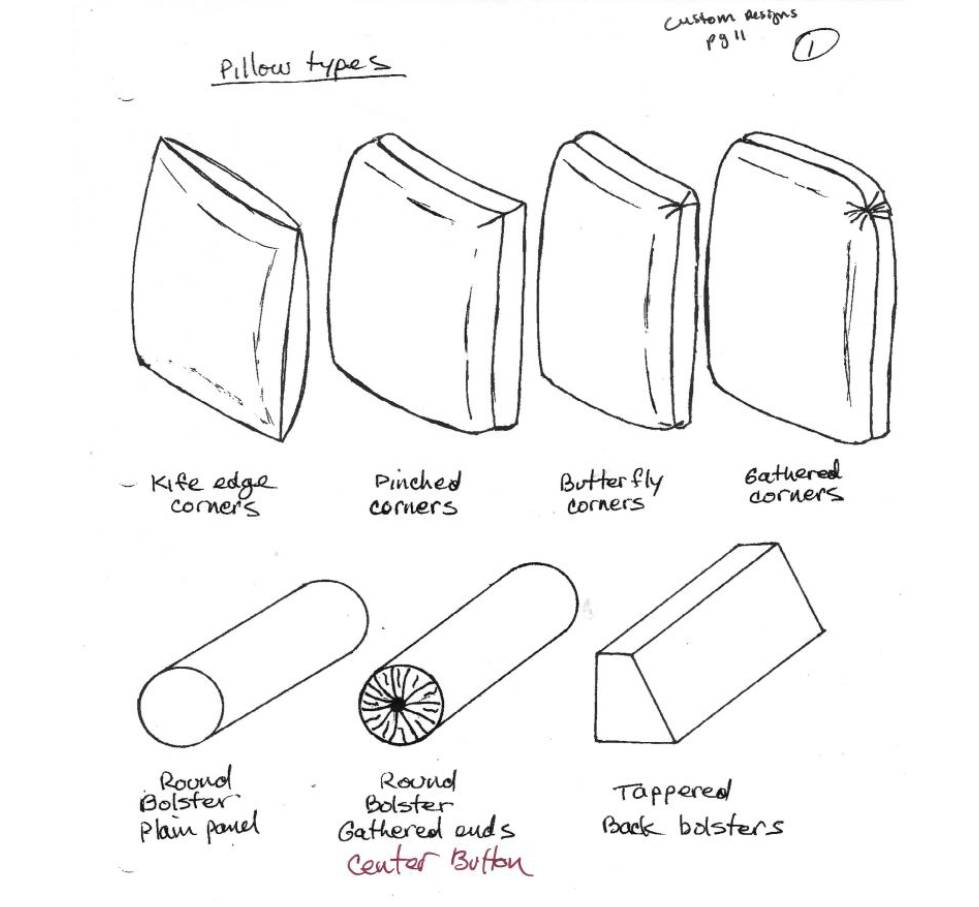

Knife-edge Style: Has a rounded finish look. Wrap around cushion with a center seam. Ends can be finished with pinch corners, butterfly corners or gathered corners. This style cushion can be finished with or without welt.

Bull-Nose Style: Has a rounded finish look. Wrap around cushion with no seams on front of seats or tops of backs. Seams are used on sides, bottom and back of cushion. All seams can be joined with or without welt.

Choice of Downs

Down/Feather: 25/75 Grey Duck down is our preferred standard down of choice. It consists of 25% down, and 75% feather blend. This down blend works well on lighter fabrics. It is airy and supportive, even when used with heavier fabrics. 50/50 down, which consist of 50% down, and 50% feather blend. Are available for an additional charge. Be careful when using lighter, more luxurious down combination with heavy fabrics. The heavier fabrics will weigh on the lighter downs. The extra weight causes the finished product to feel empty. To compensate, over packing or crowding the down may be necessary in order to fill. This over crowding process eliminates the natural behavior of the down.

Tip: You should never overstuff a down cushion. If a firmer cushion is what you are looking for you might want to consider a different type of fill.

Poly Down: A Poly down cushions is made with two 25/75 or 50/50 down envelopes joined together. Four cushion tops are traced from the finished cushion covers and cut out of a high quality down proof ticking. Two envelopes are made by sewing two tops together with 2-3 channels in between each envelope to separate the down (larger cushions take additional channels) Then the two tops are joined together by a strip of ticking called the cushion boxing (boxing varies in width depending on thickness of foam used). The boxing makes a pocket for the foam core. High resilient top rated HR foam is used along with a resilient 100% polyester wrapping. The polyester wrapping helps keep the down lofty. Springs down cushions are also available. Smaller seat cushions are not recommended with poly down fill. Smaller cushions compress the down too much and do not allow the down.

Cutting Corners

Manufactures are always looking for ways to cut comers. Here are some ways they cut corners with down cushions:

- Cheaper less resistant down proof ticking are used.

- 90% feather 10% down combinations are used.

- Only two cushion tops are cut out of down proof ticking on poly down cushions. The two interior tops of the envelope and the channels use in between the envelopes to separate the down are made of a cheaper fabric that traps the down and causes it to cluster.

- 90% feather 10% down combinations is further reduced in quality by blending it with large amounts of polyester fiber. In most cases larger percentages of polyester used than down. This also cause the down to cluster and not flow properly.

- Poorly rated foams are also used.

Knops Upholstery not only uses the highest rated foam, but we also use the, down proof ticking with the highest tread count available. We use our ticking on all interior tops and channel to provide maximum flow for all of our high quality downs, clustering is not a problem.

Filler